|

SPECIALTY PRODUCTS

DSI09 Digital Speed Indicator

- Affordable hand-held battery

operated tachometer

- Gives flexibility to test

inches-per-minute (IPM) from one station to next in short

amount of time

- C-MOS single chip

microprocessor for high reliability and low maintenance in

rugged die-cast aluminum housing (storage case included)

- Displays wire feed rate in

IPM

- Five-digit .47" (12 mm) high

LCD with automatic floating decimal point

- Checks wire speed of any

size welding wire coming out of torch head or anywhere

there is an exposure window of at least 2" (51 mm) of

welding wire

- To test IPM of welding

station during welding cycle when there is no exposed

welding wire, use Weldmatic's WEK09 Wire Exposure Kit

|

|

|

DSIB-WEA09 Digital Speed Indicator Bracket

- Bracket for holding

DSI09 Digital Speed Indicator comes complete with

WEA09 Wire Exposure Assembly attached (DSI09

sold separately).

- Quick connect fittings

snap into Weldmatic's conduit quick connectors to hold

the DSI09 in your welding system for extended

testing time.

- Spring-loaded bracket

keeps the DSI09 against the welding wire while

testing the IPM.

- Bracket allows the

DSI09 to be rotated counterclockwise then pulled

back onto a locking pin to disengage the DSI09

while readings are not needed. The DSI09 can

quickly be reengaged by pushing forward then rotating

clockwise to test the IPM of the welding wire.

|

|

|

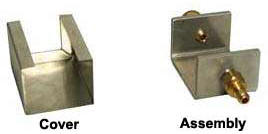

WEK09 Wire Exposure Kit

- Kit comes with WEA09 Wire

Exposure Assembly and WEC09 Wire Exposure Cover

- Kit quick connects into

existing Weldmatic quick connectors on welding station to

allow testing of wire's IPM feed rate during

welding cycle

- Simply remove WEC09 Wire

Exposure Cover to expose wire for testing

- Use cover to close system

back up to protect welding wire from dust and other

contaminates when not in use

- Allows for quick testing at

a station without hard wiring the tachometer

|

|

|

DPG09 Digital Pull Gauge

- Hand-held digital pull gauge

checks drag on wire being pulled through conduit

- State-of-the-art technology

allows for accuracy of 1/10 ounce (2 grams)

- Five-digit LCD display reads

in pounds/ounces or metric (kilograms/grams)

- Maximum pull 12 lbs (5.4 kg)

- Displays largest draw per

pull

- Gauge gives an average of up

to 10 pulls

- Includes 9 volt battery

- Storage case included

|

|

|

WC7 One-Way Wire Clutch

- Prevents wire from

retracting in the event

breakage occurs (install as close to wire source as

possible)

- Prevents wire from shingling

down on reel of

wire in the event of a breakage

- Used with 7-1 Wire Clutch

Mounting Adapter

- Maximum wire diameter

3/32" (2.381 mm)

|

|

|

7-1 Wire Clutch Mounting Adapter

- Inserts into an existing

3/8" (9.5 mm) I.D.

mounting hole leaving a 3/8" (9.5 mm) I.D.

mounting hole on other end of 7-1 for conduit

- Inserts into top of WD12

Wooden Reel Wire Dispenser

- Inserts into 6-3 Conduit

Mounting Bracket already mounted in an AH6 Accessory Holder (6-3

and AH6 sold separately) when using W10 Wooden

Reel Wire Dispenser

See link below for illustration

- Used to mount WC7 One-Way

Wire Clutch.

WD10 OPTIONAL

ACCESSORIES |

|

REPLACEMENT &

INSTALLATION DOCUMENTS

PRODUCT INDEX

PRODUCT INDEX

|

Want the Latest News from Weldmatic, Inc.?

|

Weldmatic, Inc.

P.O.

Box 1322, 2270 32nd Ave. East, Columbus, NE 68602

402-564-1808 · Toll-Free

888-564-1808 · FAX 402-564-1825

Contact Us · Order

our Products

by

McGee Designs, 2016-2025

by

McGee Designs, 2016-2025 |